Value Delivered

EMCOR Services Northeast’s (ES Northeast) turnkey design-build single source project delivery provided this hospital with a more energy efficient chilled water system in minimal downtime. The new system reduced energy consumption by an average of more than 196,152 kilowatt hours (29 percent) per year and earned the hospital a $98,076 rebate from Eversource.

We used environmentally responsible practices for equipment demolition and refrigerant disposal, and our expert rigging management helped to optimize patient and street level safety.

Client Objectives

The hospital needed a more energy efficient cooling system that would include a new chiller, pumps, and an updated automation system to help maximize the chiller’s capabilities. The system also needed to be installed with minimal disruption.

Solutions

To help minimize downtime, ES Northeast completed much of the work during the winter months when the cooling system could be offline. Our team developed a 3D CAD model of the mechanical room to help optimize the use of prefabrication.

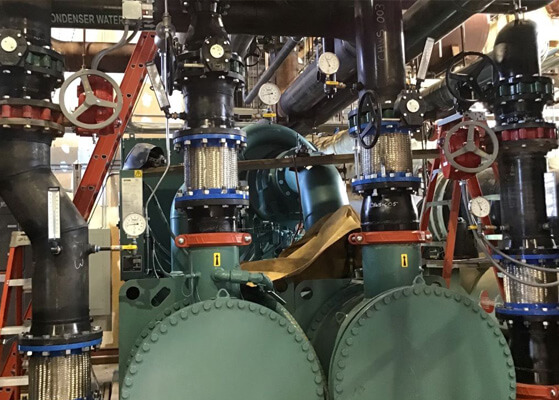

The condenser and primary chilled water loops were re-piped to allow each original pump and tower to connect to both chillers. Then we insulated the chilled water piping and installed new variable frequency drives on the pumps.

Next, a new, energy efficient, central processor-controlled chiller was installed with a frictionless compressor and new associated pumps. Since frictionless compressors operate most efficiently on partial loads, our design engineers programmed the control strategy and its algorithms to enable an all-variable-flow central plant with system components regulated for maximum energy efficiency.

The lead/lag staging capability of our solution helped improve performance, enabling the chillers, compressors, pumps, variable frequency drives, and cooling towers to adjust to changing environmental conditions.

To finalize the project, we tested and balanced the chilled water system and performed commissioning and startup. In addition, we provided the client with the chiller manufacturer’s performance data and trained the client’s facilities personnel on the operation of the chiller and new controls system.

Client Background

This facility includes two hospitals and a network of supplementary service centers throughout Boston’s western suburbs.